Last week I ordered a $300 embroidery machine off of Amazon. Fully acknowledging that most embroidery machines are $1000+, and that a good sewing machine starts around $300, I set my expectations accordingly. I knew it wasn’t going to be a great machine, but I also didn’t want to spend much more until I’m sure that machine embroidery is for me. Here’s what I’ve learned:

Cheap machines are a tensioning nightmare

Actually I already knew that, but the Brother SE400 reminded me how true it is. The tension on the Brother SE400 is fiddly. It’ll start skipping stitches, then I’ll rethread it, and it will sew just fine. Or it dislikes the bobbin for some reason. I can get it working, but every time I rethread it (more on that in a minute) I have to cross my fingers that it’s happy. Maybe I’m spoiled by my all-mechanical Janome, but I’m not to keen on the mysticism required to get the thing tensioned properly.

I really want a multi-needle machine

With a single needle machine every color change means rethreading. And on the SE400 every rethreading is an opportunity to make it angry. Plus occasionally I just screw up. I find myself loath to do designs with more than 5 or so colors because I don’t want to sit there changing them out every 5 minutes. If I was planning on doing any sort of production work a multi-needle machine would be a must.

The 4×4 work area is too small

The advice given in almost every “how to pick a machine” article is “get the biggest work area you can afford,” and it’s true. Even if you only want to embroider small stuff. Why? Because the 4×4 work area means you have to get your hoop placement just right, and on many items that’s a real big pain in the arse. It also means re-hooping if you want to place multiple designs on a garment.

The touchscreen LCD kind of sucks

When you’re stitching out a design it can show you the color info (handy if you’ve got a 10+ color design) or the stitch count, but not both, and switching between the two requires multiple button presses. Which wouldn’t be so bad except the touch registration on my machine is slightly off. This means that when I go to step back one stitch I often end up stepping forward an entire color (those two buttons are adjacent). I’ve learned always to write down the stitch count before touching anything.

Getting your own designs into the machine is easy… if they’re digitized

To download new designs you just plug the machine into your computer’s USB port and it presents itself as an external drive to drag / drop PES or DST files onto. Great! Seriously, this could have been way more painful and I was glad it was so easy.

That said, it turns out that digitizing files (going from a bitmap or vector to stitches) is a hobby in and of itself. Digitizing software is expensive (hundreds or thousands of dollars), and learning to do it takes practice. There’s auto-digitizing software available, but I haven’t heard many positive things about the quality of stitch outs produced. The conventional wisdom of the internet is to pay a professional to digitize your files if you don’t want to invest the time and money to do it yourself.

The good news is that pro digitization is cheap, generally $10-15 for a simple design. I found someone on Etsy who turned it around in a couple of days.

Despite its flaws, it’s still a fun machine

It won’t win any awards but it’s not a bad machine, and very fairly priced.

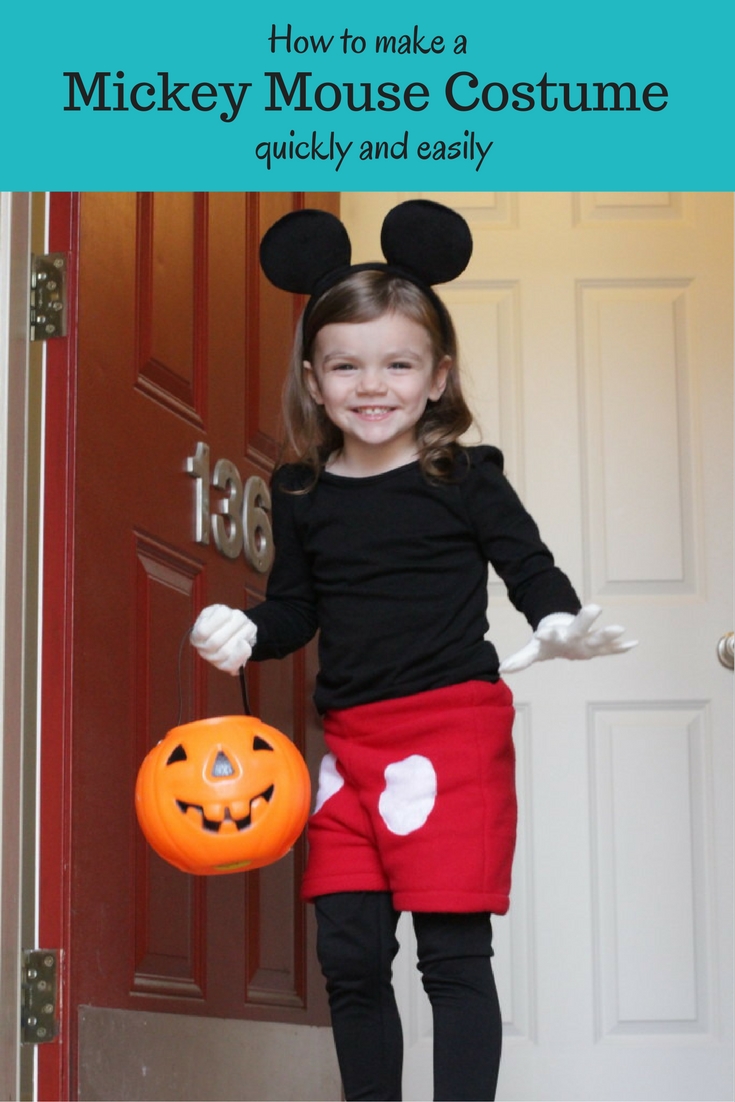

I made a hoodie for my nephew and the embroidery on it is completely adorable. I put my husband’s business logo on an old tote bag and he was stoked. And I’m learning a lot about the basics of machine embroidery. Which stabilizers to use with which fabrics, getting practice hooping things correctly, it’s all a learning process that will translate well to whatever machine I eventually upgrade to.

The use cases where I’d suggest buying a Brother SE400 are admittedly minimal. If you’re at all serious about embroidery, save up for something with a larger work area. While it does dual duty as a sewing machine, it’s not a particularly good one so if you primarily want a sewing machine I’d suggest putting the $300 towards a nice basic machine. I figure in 6 months when I have a really solid idea of what I want in a machine I’ll trade it in towards something fancier. Until then, expect to find it whirring in the background while I work.